Introduction to Block Valves (On-Off Valves)

GOALS for this module

- Provide valve definitions and key concepts

- Introduce different design options for block valves

- Present the key features of selected block valve designs

- Introduce the API 6D specification for valves

- Provide the information required to specify/purchase a block valve

--------------------------------------------------------------------------------------------------------

DEFINITIONS and KEY CONCEPTS

What is a Valve?

A valve is a mechanical device used to control the flow of a fluid (such as gases, liquids, or slurries) through a system of pipes or tubes.

What are the main types of valves?

- Block valves: valves that block the flow when in closed position. Aka "On-off valve".

- Warning: a block valve should be used in fully open or fully closed position only, not in partially open position for throttling.

- Control valves: valves that regulate the flow by varying the size of the flow passage as directed by a signal (e.g. temperature or pressure) from a controller.

- Pressure relief valves/Safety valves: valves that limit the pressure in a system by automatically discharging the pressure when it exceeds the set point.

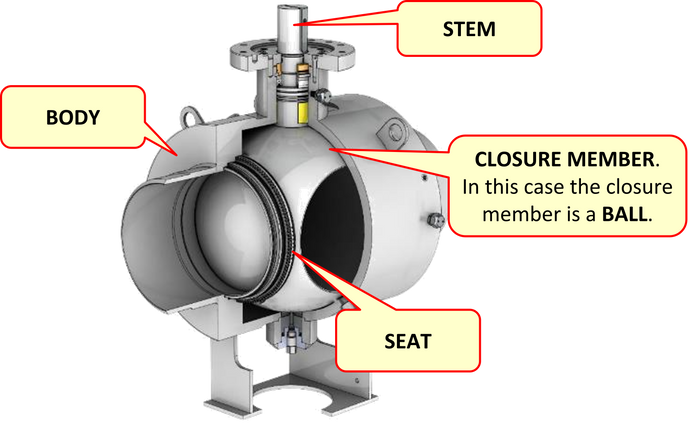

What are the key components of a block valve?

- Body: the valve body is the pressure containing component, preventing external leaks (i.e. release of contained fluid into the environment).

- The body is usually made of forged parts or cast parts.

- Closure member (aka "Obturator"): it is the part of the valve that permits or prevents flow through the valve. It is the component that qualifies the type of valve.

- In our presentation it can be a Ball, Gate, Plug, or Disc.

- Seat: it is the part that contains the surface upon which the obturator rests to prevent flow through the valve.

- It can be metal-based or "soft" (with either an elastomeric or polymeric seal); fixed or spring loaded.

- Stem: it is the part that drives the closing member and allows for opening-closing operation.

BORE SIZE

Block valves can be categorized based on the size of the bore within the closure member, commonly referred to as "port size".

- When the bore size matches that of the pipe, the valve is known as a "Full Opening Valve" also referred to as "Full Port".

- If the bore size is smaller than that of the pipe, the valve is referred to as a "Reduced Opening Valve", sometimes known as "Regular Port".

It is important to note that valves featuring non-circular openings within the closure member should not be classified as full opening valves.

Furthermore, valves with a reduced opening result in a more significant pressure drop across the valve compared to full opening valves.

DESIGN OPTIONS

The most common design options, based on the type of closing member, are:

- Ball valves

- Gate valves

- Plug valves

- Butterfly valves

The tables below offer a quick snapshot of the key features of each design type.

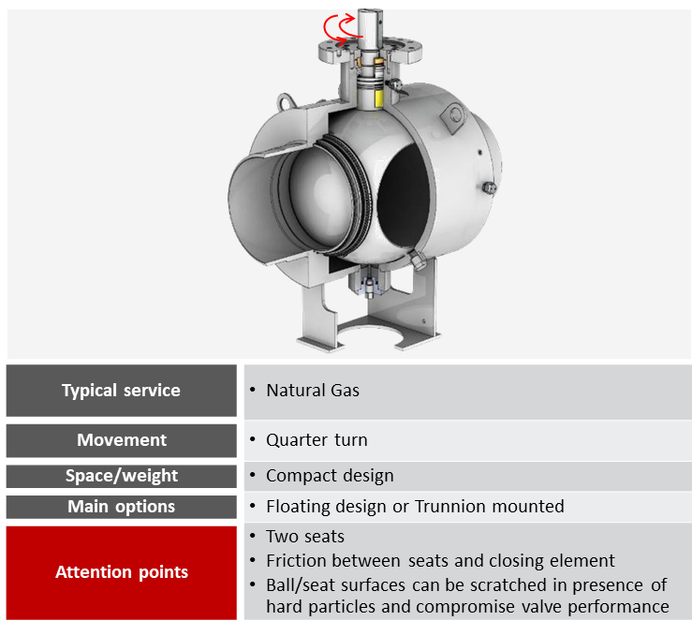

BALL VALVES

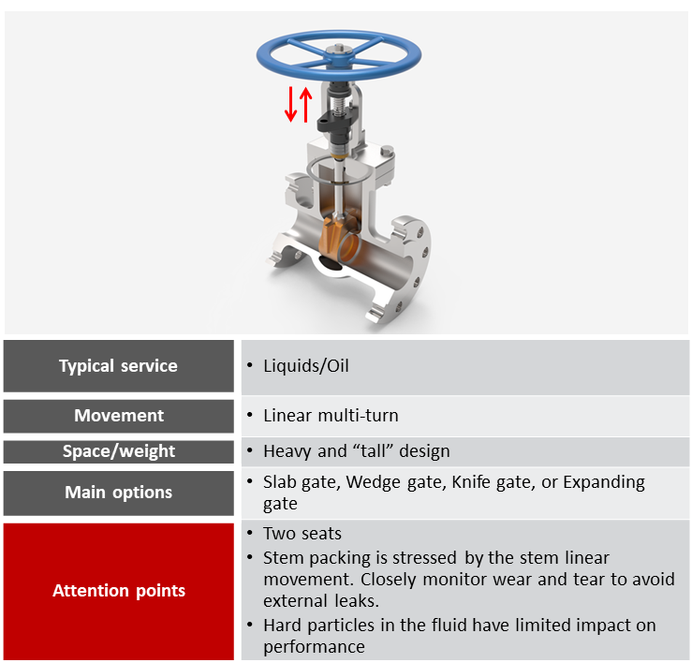

GATE VALVES

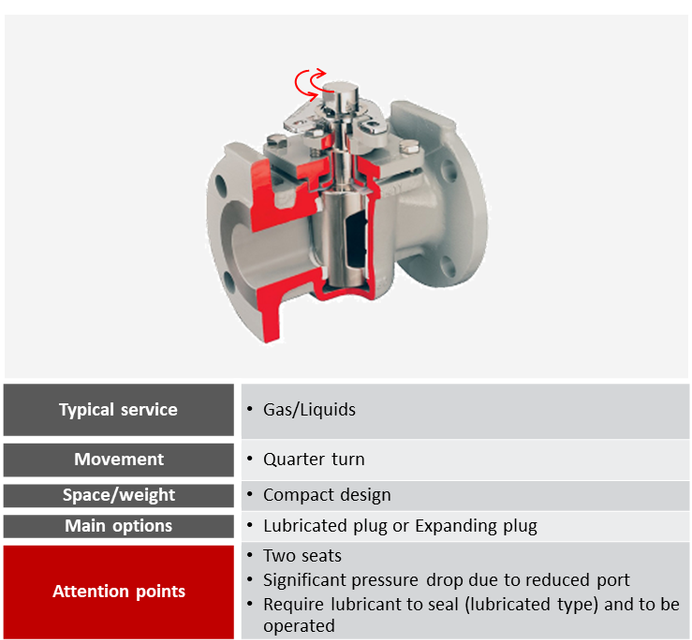

PLUG VALVES

BUTTERFLY VALVES

INTRODUCTION TO THE API 6D SPECIFICATION

What is API?

The American Petroleum Institute (API) is a trade association in the United States that primarily serves the oil and natural gas industry. It was founded in 1919 and has since played a significant role in the development and promotion of industry standards, best practices, and advocacy for the oil and gas sector.

What is API 6D?

API 6D is the specification that defines the requirements for design, manufacturing, materials, welding, quality control, assembly, testing, marking, documentation, and process control of axial, ball, check, gate, and plug valves for application in the petroleum and natural gas industries.

Why is API 6D important?

API 6D is an industry recognized standard and its compliance is frequently required for valves for oil & gas applications.

PHMSA (the Pipeline and Hazardous Materials Safety Administration, which is part of the US Department of Transportation) requires API 6D compliance for all the valves used in Gas Transmission systems in the USA. Compliance to API 6D ensures quality, safety and purpose fitness.

INFORMATION REQUIRED TO SPECIFY/PURCHASE VALVES

When you specify/purchase valves there is a minimum set of basic information that is required to be transmitted to the supplier to make sure the valves will meet your expectations.

Additional information is also highly recommended.

Minimum set of basic information

- Valve design option

- For example: Ball OR Gate OR Plug OR Butterfly

- Valve Size

- In North America, size is normally expressed as NPS (Nominal Pipe Size), which is typically measured in inches (can be dimensionless). In Europe, it is normally expressed as DN (Nominal Diameter), which is typically measured in mm (can be dimensionless).

- For example: NPS 2" OR DN 50.

- Pressure-temperature rating

- Typically expressed by a class numbers, as defined in ASME B16.34. Classes are defined as the maximum pressure that the valve can withstand at a specific temperature, for each steel group. The class selected should correspond to the intended maximum pressure and temperature range for the valve's intended usage.

For example: Class 150 OR Class 600. - Warning: please note that Class 150 does not mean that the valve is rated for 150 psi (or 150 bar). Just as a reference, the Maximum Acceptable Operating Pressure (MAOP) for a carbon steel valve (for example, made in A105) is 285 psi when used between -20F and 100F. The MAOP for the same valve at 500F is 170 psi.

- Typically expressed by a class numbers, as defined in ASME B16.34. Classes are defined as the maximum pressure that the valve can withstand at a specific temperature, for each steel group. The class selected should correspond to the intended maximum pressure and temperature range for the valve's intended usage.

- End connections

- For example: Flange by Flange (or FxF) OR Weld by Weld (WxW).

- In the case of flanges, the type of flange, for example RF (Raised Face) or FF (Flat Face) or RTJ (Ring Type Joint), and the flange standard (ASME B16.5, etc.) should be specified.

- In the case of weld connections, the thickness of the pipe and the pipe material should be specified.

Additional information - recommended

- Fluid

- For example: clean natural gas OR sour gas with 15% H2S.

- Operating conditions

- Operating temperature range; Operating pressure range.

- Port Size

- Full Port OR Regular Port

- Specific materials, as needed

- If any specific material is needed/preferred for the steel body (e.g. A105 or A350 LF2) or for any other components, like the seat (e.g. PTFE/Teflon or HNBR).

- Type of Operator

- For example: Lever handle OR 2" square nut OR gear operator (with vertical/horizontal input; with or without handwheel) OR actuator.

In case of actuator, additional information is required.

- For example: Lever handle OR 2" square nut OR gear operator (with vertical/horizontal input; with or without handwheel) OR actuator.

- Type of painting/coating

- For example: epoxy coating for buried service OR manufacturer's standard.

- Compliance requirements to specific standards or design codes

- For example: API 6D.

Many valve users developed their own valve specification. In that case, please share the specification with your valve supplier.

Also, many valve users have their own Approved Vendor List (AVL) or Approved Manufacturer List (AML). These are documents that include the vendors/manufacturers approved for supplying a specific type of equipment (for example: valves OR actuators). Usually, the process to add a new Vendor/Manufacturer on an AVL/AML entails a detailed scrutiny, that includes desk activities (analysis of drawings, references, quality system, certifications, etc.) and an on-site audit/inspection at the manufacturer's facility. If you have an AVL/AML for valves, please share it with your valve supplier.

------------------------------------------------------------------------------------------------------------

Congratulations for completing this training module!

Check your knowledge by taking a test.

You will receive a training certificate by email upon completion.

Start the test by clicking the button below.

------------------------------------------------------------------------------------------------------------

If you have any comments on this training module, please reach out to us at info@broen.com